Nous n'avons pas créé PANAFRICA pour vendre des baskets. Nous l'avons fait pour construire un modèle différent.

En 2015, nous décidons de tout quitter et de nous lancer avec une idée forte : fabriquer des baskets, inspirées de l’Afrique, sur le continent africain, en maîtrisant la production, en créant de l’emploi local, et en construisant un projet qui a du sens à chaque étape. On prend notre sac à dos, on parcourt des milliers de kilomètres : Maroc, Burkina Faso, Bénin, Côte d'Ivoire, Ghana : aller là où est la matière, là où sont les artisans.

Depuis, PANAFRICA est devenu bien plus qu’une marque. C’est une aventure industrielle et humaine. Un projet qui conjugue esthétique, exigence et engagement. On ne fait pas du “made in Africa” un concept marketing. On produit en Afrique. Vraiment.

Bienvenue dans l'aventure !

A DROP OF SUMMER

NOTRE VISION ?

Faire de la mode un levier de transformation sociale et environnementale en Afrique.

Notre mission ?

Créer des baskets qui soutiennent les artisans locaux et contribuent à des initiatives environnementales et sociales en Afrique.

QUELQUES CHIFFRES

140 000

Followers sur les réseaux sociaux ! Rejoignez-nous !

130

Points de vente sélectifs dans une quinzaine de pays

80

Emplois créés dont 40 emplois directs dans notre atelier de production en Côte d'Ivoire

NOS PARTENAIRES

Nous fabriquons des produits qui ont du sens.

Le sens c’est la transparence, c’est l’écoute, c’est la connaissance des femmes et des hommes avec qui nous travaillons main dans la main, c’est la fierté de construire un projet durable avec un impact positif, c’est remettre en question nos habitudes pour avancer vers une mode toujours plus engagée et humaine.

Pour réaliser nos collections nous travaillons main dans la main avec nos partenaires talentueux qui sont devenus au fil du temps de véritables compagnons de route. Ils sont au cœur de notre projet et sans eux rien ne serait possible.

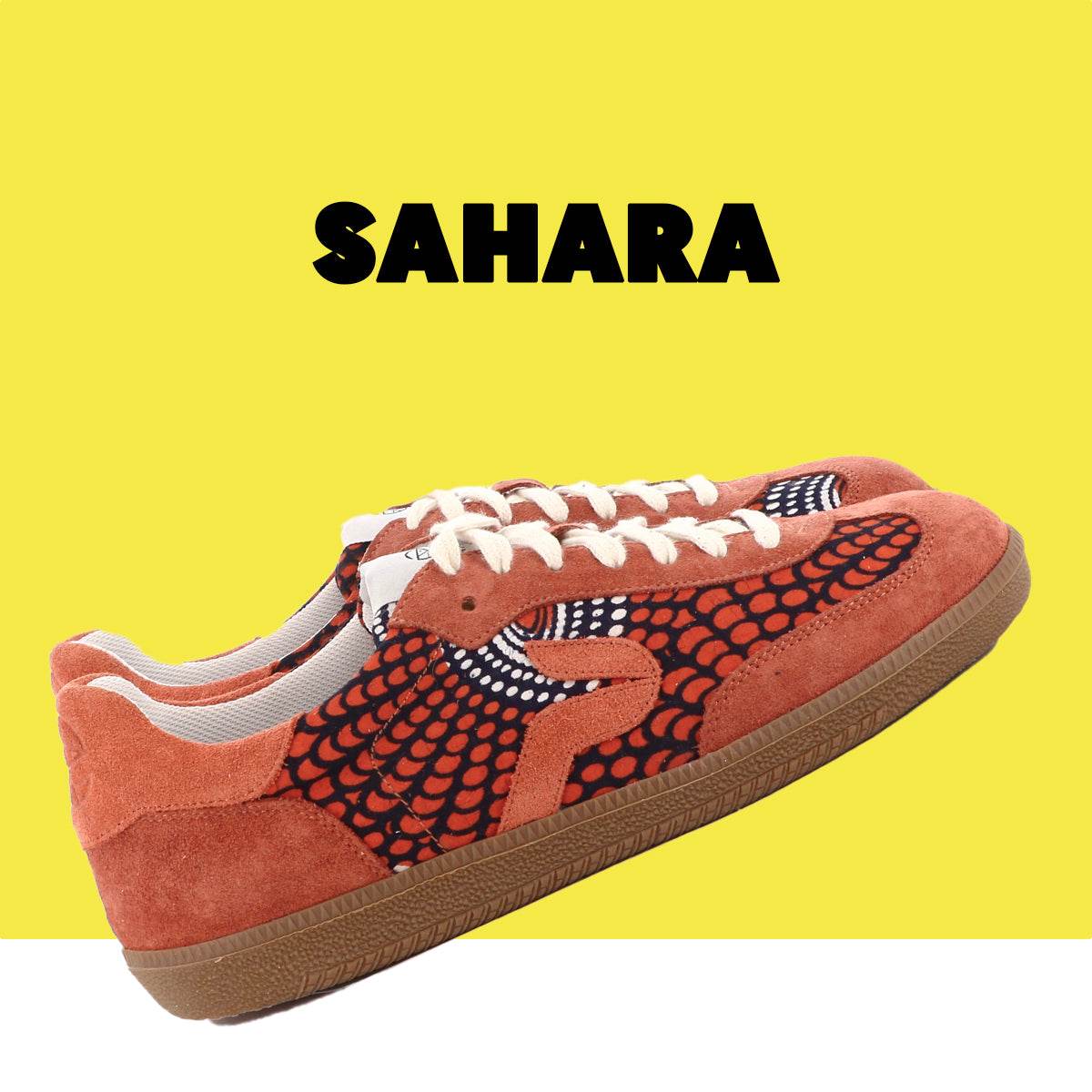

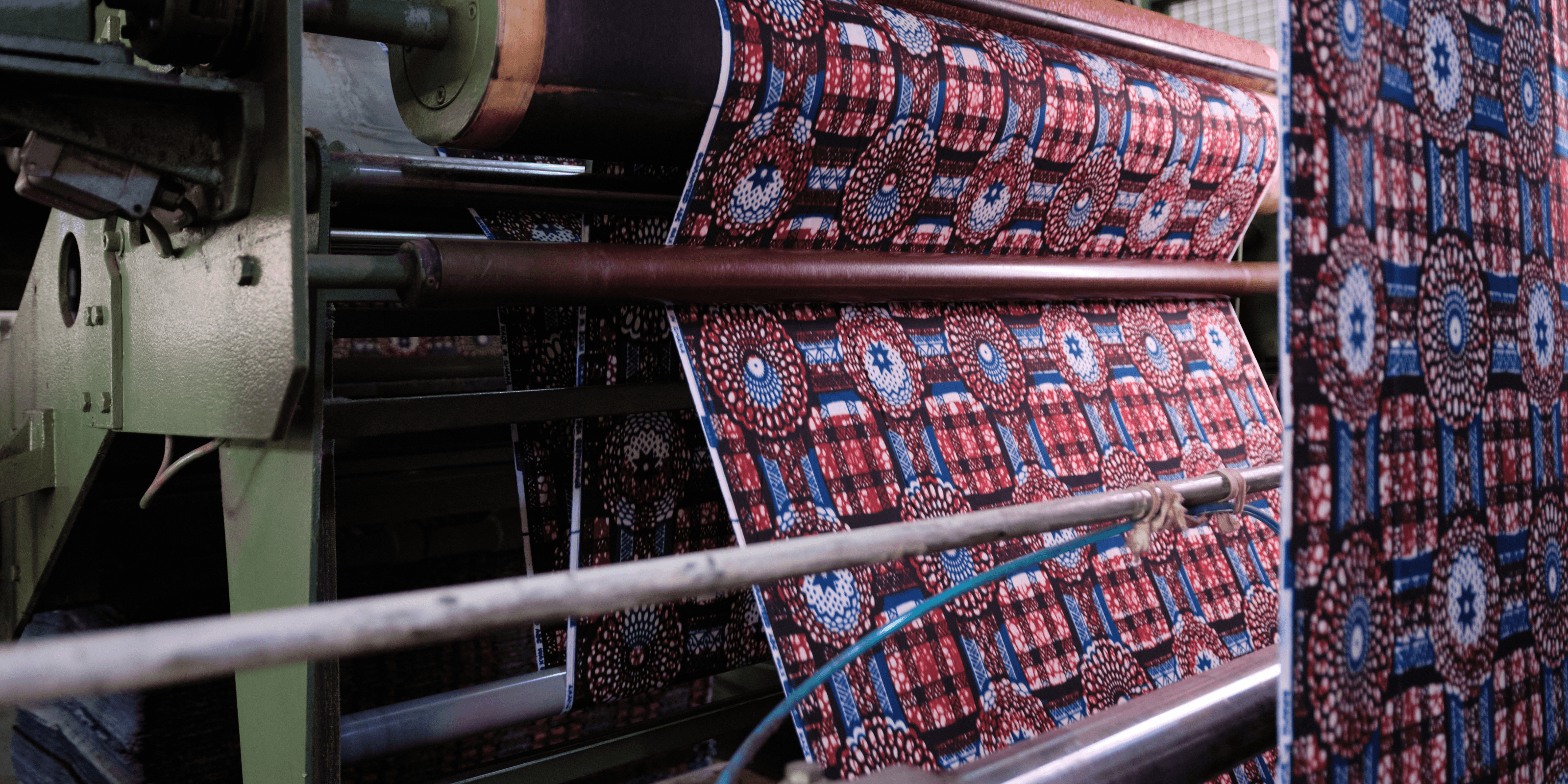

Depuis sa création en 1968, Uniwax est le leader ouest africain de l’impression du wax. Ses produits, vendus sous les marques Uniwax et Woodin, sont exportés dans plus d’une dizaine de pays d’Afrique de l’Ouest et d’Afrique Centrale. Uniwax fait appel à différents procédés pour réaliser sa gamme de produits. Les tissus sont enduits de cire puis teints avec un procédé spécifique garantissant une très grande tenue des couleurs. De la gravure des cylindres en cuivre aux bains de teinture, plus de 20 étapes sont nécessaires pour produire un motif !

Uniwax est le partenaire historique de Panafrica depuis 2015. Chaque saison, nous nous rendons à Abidjan pour sélectionner les plus beaux motifs pour nos collections. Nous avons la chance de travailler directement avec Uniwax, ce qui nous offre une grande flexibilité et la possibilité de personnaliser les motifs sélectionnés pour proposer des collections uniques.

Nous avons rencontré Esther et son équipe en 2019 et sommes tombés sous le charme de cette grande dame talentueuse et pleine d’énergie. C’est dans son petit atelier au nord d’Accra (capitale du Ghana) qu’Esther, sa fille et leurs 4 employés créent des motifs originaux et perpétuent un savoir-faire bien connu au Ghana : l’impression artisanale du Batik. Chaque saison nous développons à leurs côtés de nouveaux motifs pour nos collections.

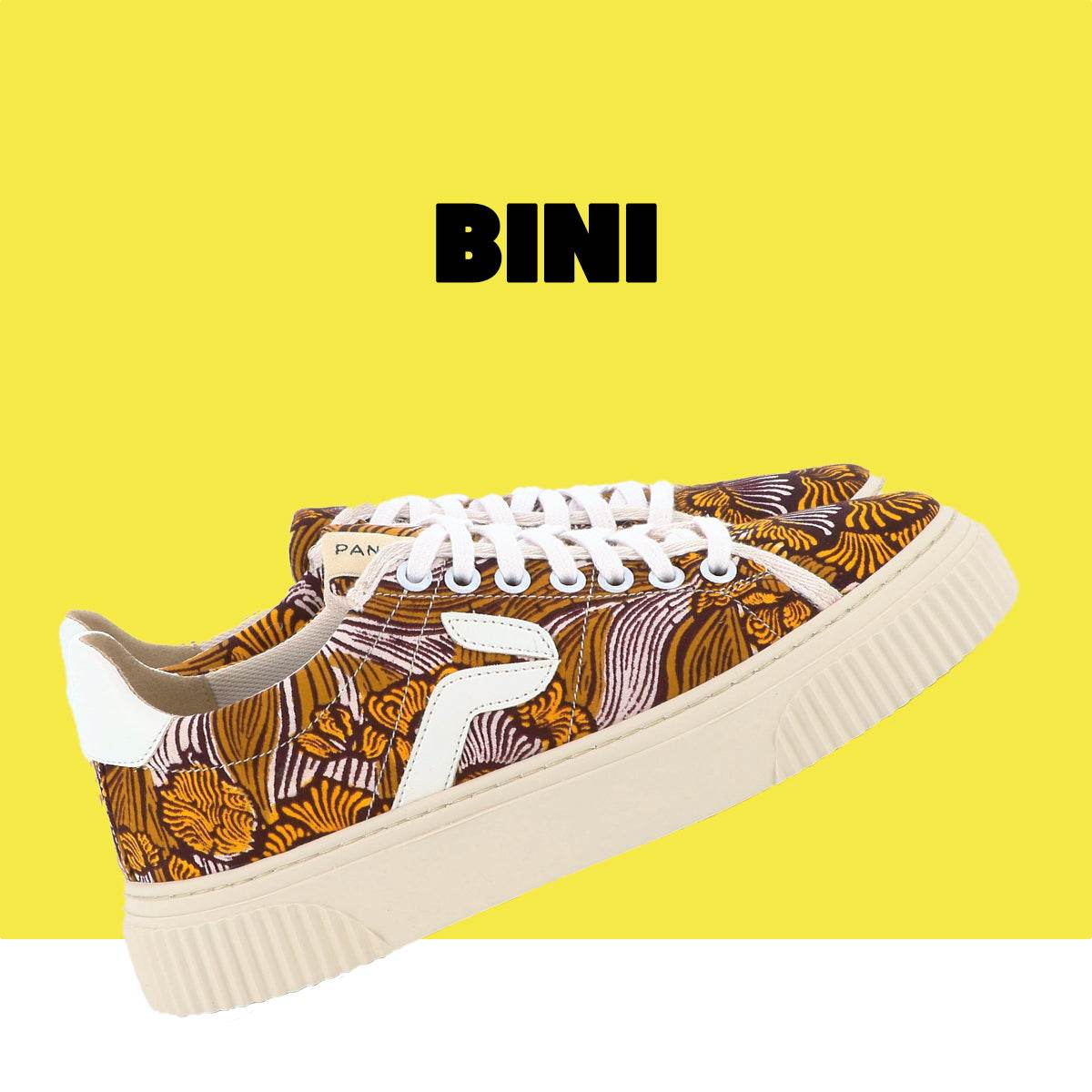

Nous achetons nos toiles de coton biologique auprès de Xoomba au Burkina Faso. Xoomba est une association fondée en 2009 pour établir une chaîne complète de production de textile en coton biologique (certifié GOTS) au Burkina Faso. Au Burkina, la pluviométrie permet la culture d’un excellent coton sans arrosage, alors que la culture du coton consomme habituellement de grandes quantités d’eau potable. Le Burkina Faso a aussi l’avantage de disposer de tous les moyens de transformation du coton : égrenage et filage.

Xoomba réalise la teinture écologique du coton à fibres réactives sans métaux lourds et travaille avec des artisans tisserands sur des métiers mécaniques ne nécessitant pas d’électricité. Xoomba emploie environ 25 personnes (principalement des femmes) qui perçoivent un salaire supérieur au salaire moyen au Burkina. Xoomba forme également de jeunes couturiers pour produire des produits finis made in Burkina afin que le maximum de plus-value profite à l’économie du pays.

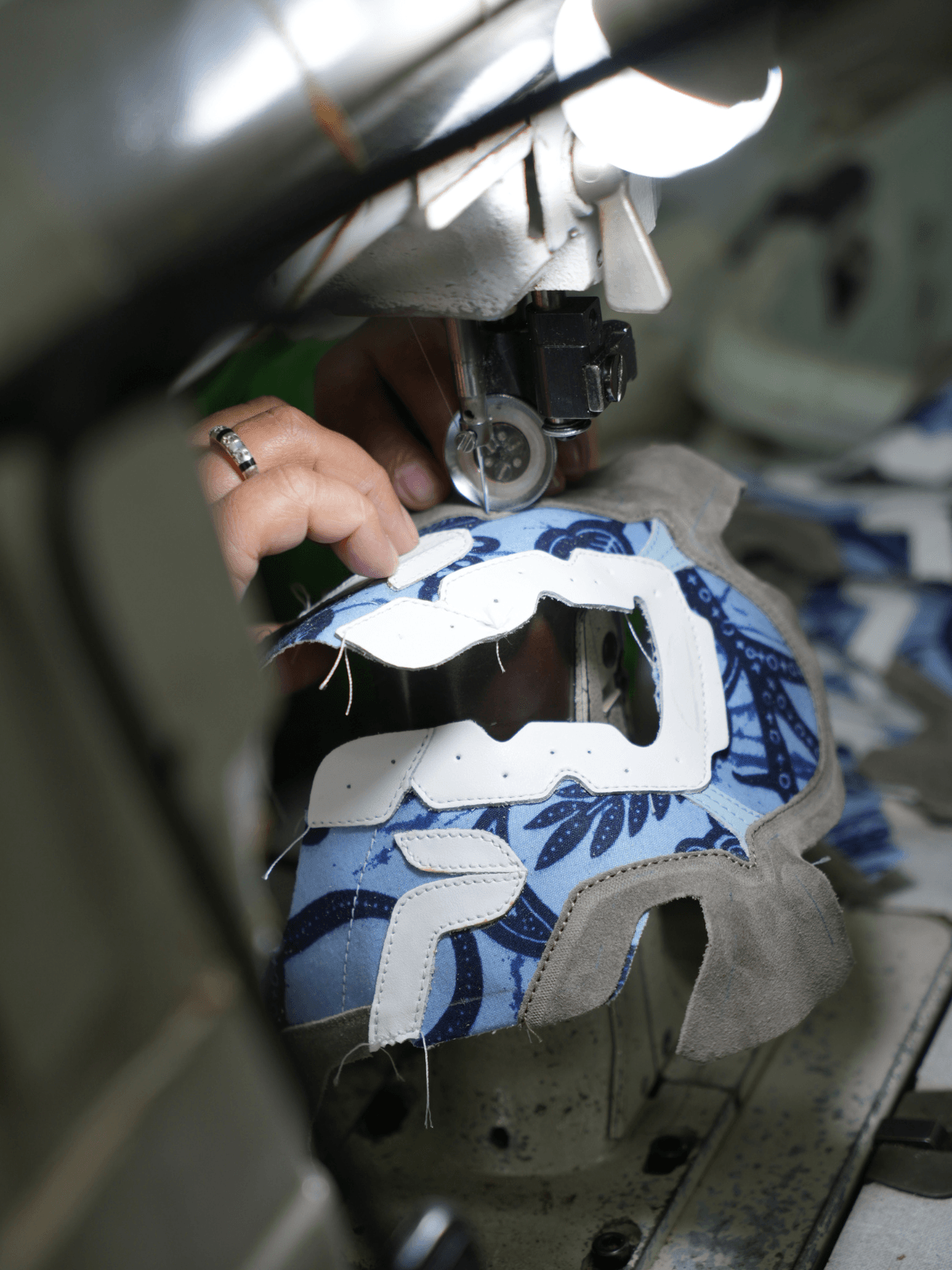

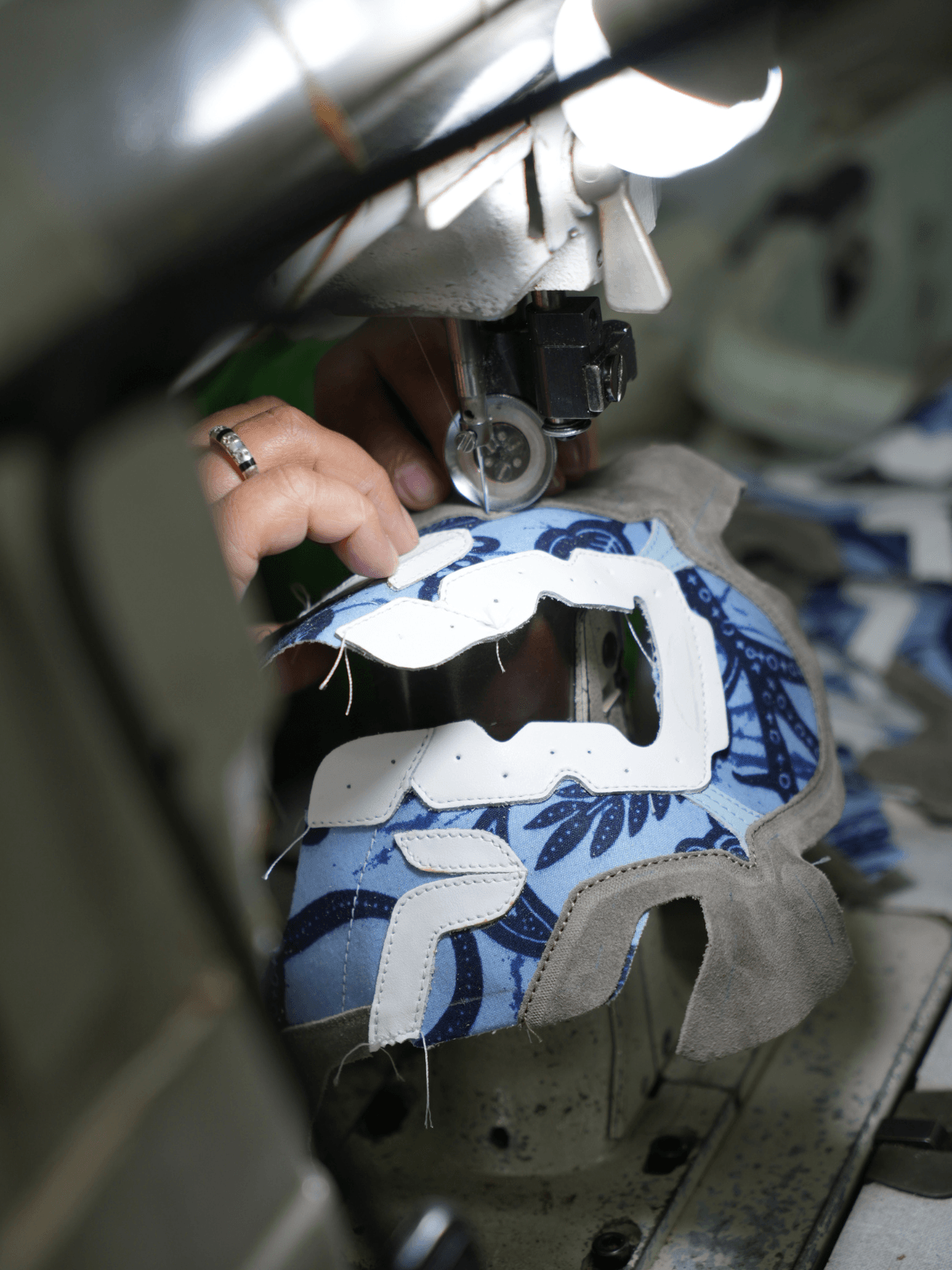

La relation entre l’atelier d’Hicham et Panafrica date de nos débuts. Lors de notre première rencontre en 2015, nous avons immédiatement senti une ambiance agréable dans cet atelier familial et un savoir-faire unique garantissant des produits de grande qualité. Très professionnel, Hicham nous accompagne pour développer nos collections.

Cet atelier est certifié par un organisme externe et respecte les règles de l’OIT (Organisation Internationale du Travail). Cela garantit un code de responsabilité sociale et assure que les baskets PANAFRICA sont fabriquées dans un environnement où les droits des travailleurs sont respectés.

Depuis sa création en 1968, Uniwax est le leader ouest africain de l’impression du wax. Ses produits, vendus sous les marques Uniwax et Woodin, sont exportés dans plus d’une dizaine de pays d’Afrique de l’Ouest et d’Afrique Centrale. Uniwax fait appel à différents procédés pour réaliser sa gamme de produits. Les tissus sont enduits de cire puis teints avec un procédé spécifique garantissant une très grande tenue des couleurs. De la gravure des cylindres en cuivre aux bains de teinture, plus de 20 étapes sont nécessaires pour produire un motif !

Uniwax est le partenaire historique de Panafrica depuis 2015. Chaque saison, nous nous rendons à Abidjan pour sélectionner les plus beaux motifs pour nos collections. Nous avons la chance de travailler directement avec Uniwax, ce qui nous offre une grande flexibilité et la possibilité de personnaliser les motifs sélectionnés pour proposer des collections uniques.

Nous avons rencontré Esther et son équipe en 2019 et sommes tombés sous le charme de cette grande dame talentueuse et pleine d’énergie. C’est dans son petit atelier au nord d’Accra (capitale du Ghana) qu’Esther, sa fille et leurs 4 employés créent des motifs originaux et perpétuent un savoir-faire bien connu au Ghana : l’impression artisanale du Batik. Chaque saison nous développons à leurs côtés de nouveaux motifs pour nos collections.

Nous achetons nos toiles de coton biologique auprès de Xoomba au Burkina Faso. Xoomba est une association fondée en 2009 pour établir une chaîne complète de production de textile en coton biologique (certifié GOTS) au Burkina Faso. Au Burkina, la pluviométrie permet la culture d’un excellent coton sans arrosage, alors que la culture du coton consomme habituellement de grandes quantités d’eau potable. Le Burkina Faso a aussi l’avantage de disposer de tous les moyens de transformation du coton : égrenage et filage.

Xoomba réalise la teinture écologique du coton à fibres réactives sans métaux lourds et travaille avec des artisans tisserands sur des métiers mécaniques ne nécessitant pas d’électricité. Xoomba emploie environ 25 personnes (principalement des femmes) qui perçoivent un salaire supérieur au salaire moyen au Burkina. Xoomba forme également de jeunes couturiers pour produire des produits finis made in Burkina afin que le maximum de plus-value profite à l’économie du pays.

La relation entre l’atelier d’Hicham et Panafrica date de nos débuts. Lors de notre première rencontre en 2015, nous avons immédiatement senti une ambiance agréable dans cet atelier familial et un savoir-faire unique garantissant des produits de grande qualité. Très professionnel, Hicham nous accompagne pour développer nos collections.

Cet atelier est certifié par un organisme externe et respecte les règles de l’OIT (Organisation Internationale du Travail). Cela garantit un code de responsabilité sociale et assure que les baskets PANAFRICA sont fabriquées dans un environnement où les droits des travailleurs sont respectés.

BON À SAVOIR

Nous avons récemment ouvert (en 2026) notre propre atelier de production et un centre de formation en Côte d'Ivoire.

Notre objectif est clair : chaque paire de baskets PANAFRICA sera conçue et fabriquée entièrement en Afrique subsaharienne par les communautés locales. Ce projet d'usine représente bien plus qu'un simple lieu de production. C'est un espace dédié à l'innovation, à l'apprentissage et au développement économique local.

Une page dédiée à ce projet est à consulter sur notre site en suivant ce lien : projet usine.

EN PRODUCTION/AUX PIEDS de nos clients

EN PRODUCTION

AUX PIEDS DE NOS CLIENTS

TRANSPARENCE

La transparence est au cœur de notre projet. Nous travaillons sans intermédiaire depuis nos débuts et connaissons les femmes et les hommes qui œuvrent derrière chaque produit Panafrica. Cette transparence est une exigence au quotidien car nous avons le devoir de vous dire ce que nous faisons, comment et avec qui.

Depuis 2016, nous construisons un projet pérenne et nous n’avons rien à cacher. A l’heure où l’écologie et l’éthique sont sur toutes les lèvres, notre devoir est de vous donner toutes les clefs de compréhension de notre projet.

De la culture du coton à notre entrepôt logistique, en passant par nos ateliers d’assemblage, PANAFRICA n’aura plus de secret pour vous…